Imagine your ordinary car at the South Pole at -40°C. It wouldn’t function reliably. It is no coincidence that polar researchers employ special devices. We often note these severe assessment mistakes of users who want to use storage technics they know from normal temperature ranges. Likewise, the risk of icing-up is likely to be underestimated when warmer, increasingly humid external air freezes on the surfaces of the cold preparations and the storage mechanics due to physical conditions; layer by layer at every loading or unloading process. We call this the glaciation effect.

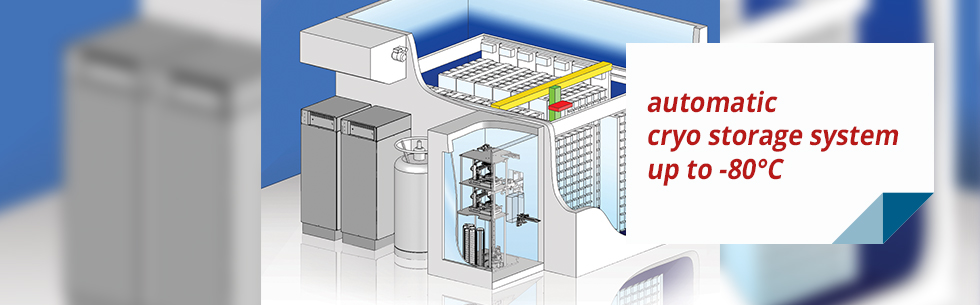

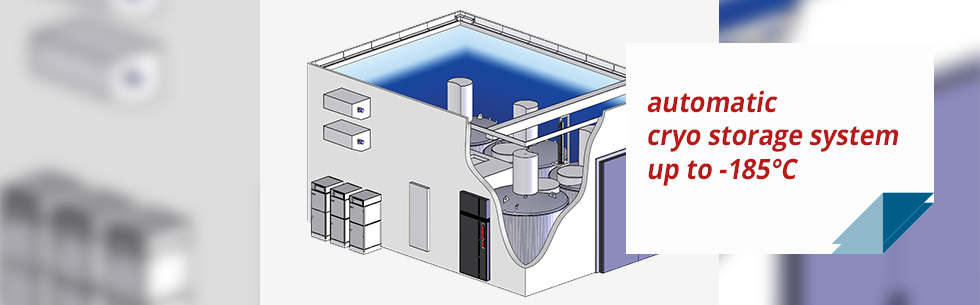

In order to minimize icing, a cryo storage system needs to be as air tight as possible. This is achievable through a high level of automation. To ensure a smooth automation it is necessary to only use materials and technics which are verifiably suitable for operation at lowest temperature, which requires long-term tests. We only use systems which fulfil these requirements.

Our cutting-edge technology.